SKD

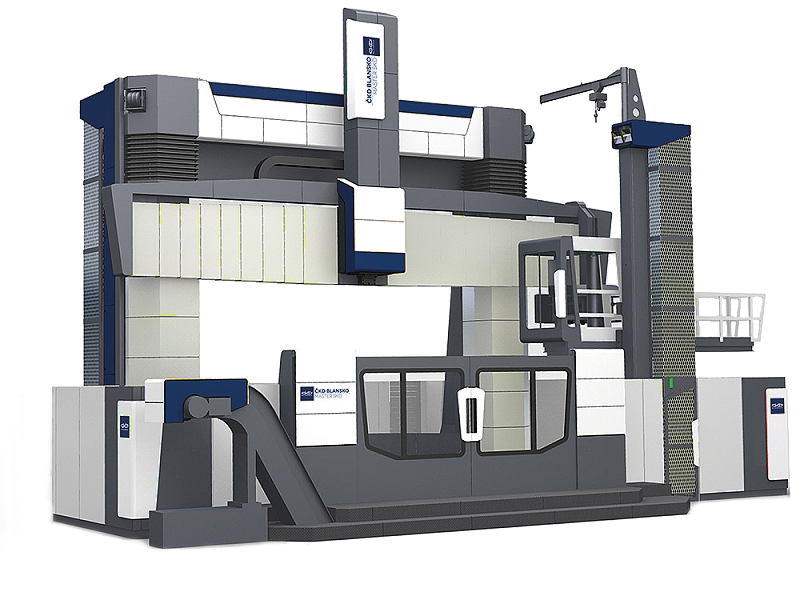

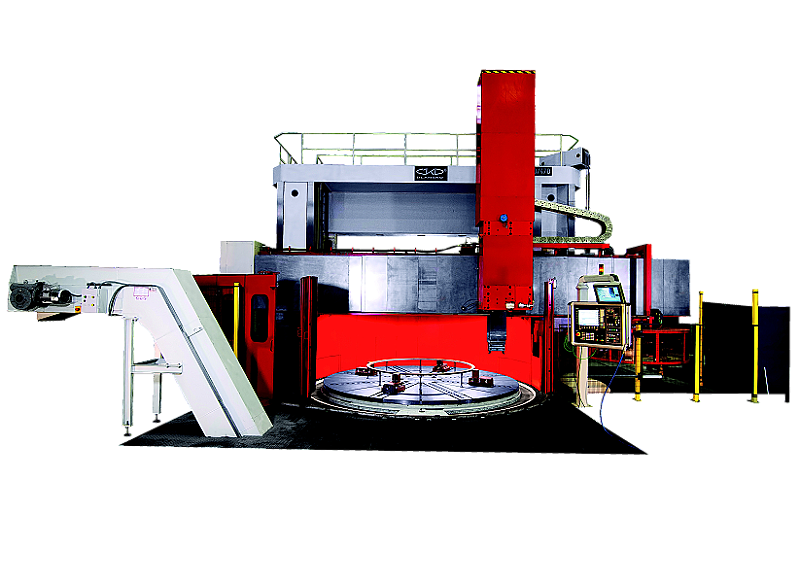

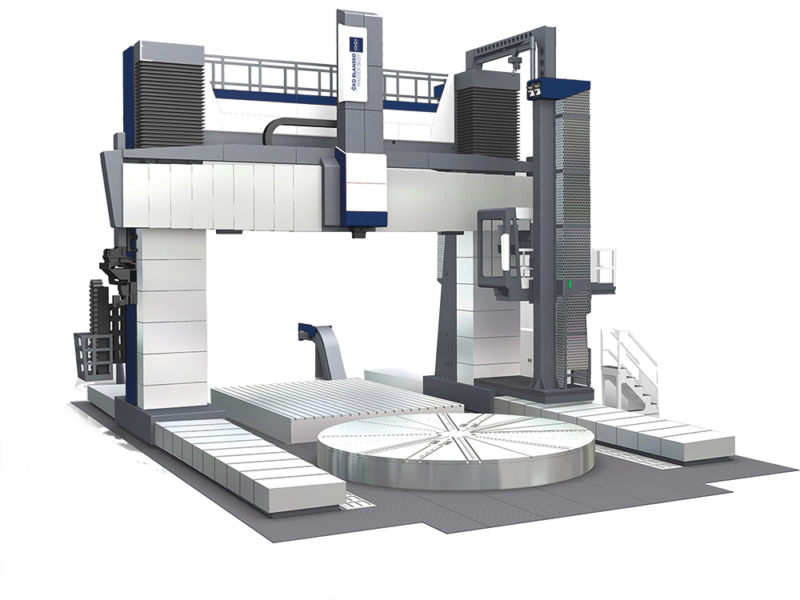

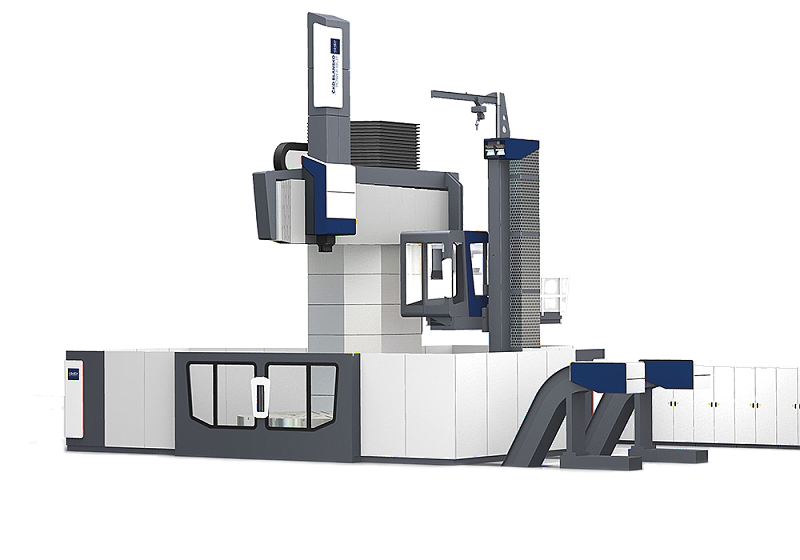

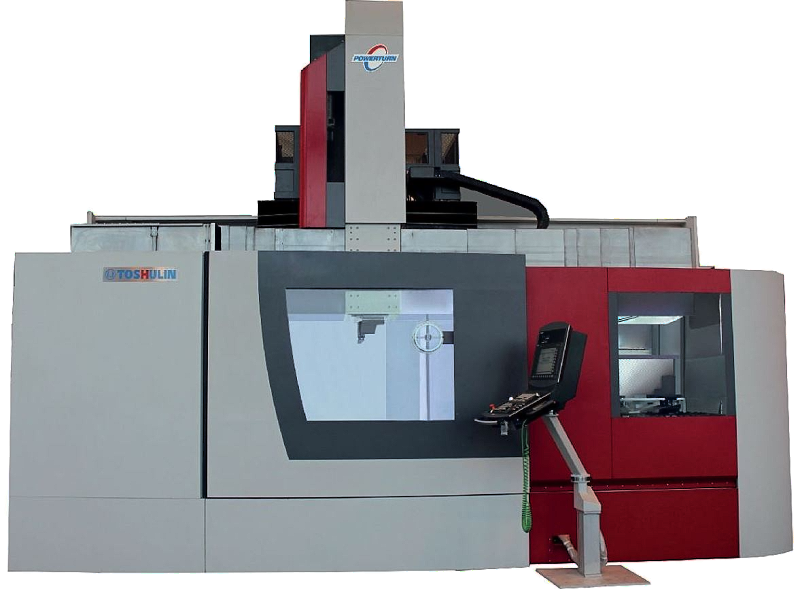

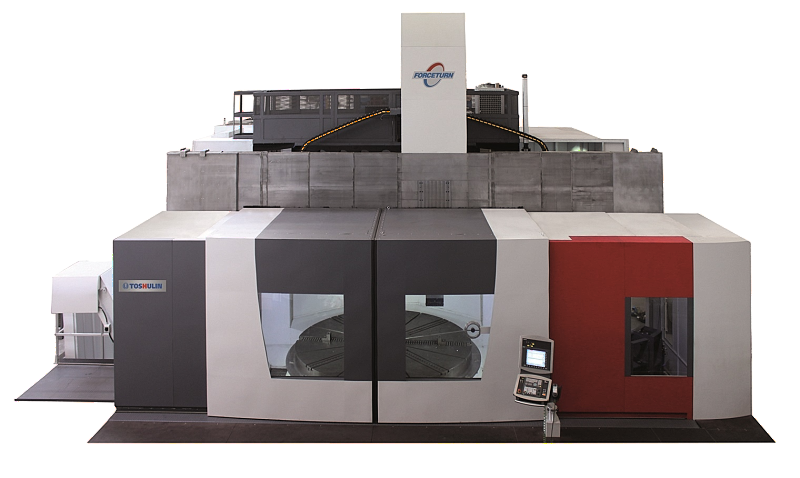

SKD – vertical turn mill center

The machine of modular design enables a considerable variability of its composition. The machine consists of the portal which is fixed on the foundation. The portal is equipped with the cross rail which is fixed in the vertical direction. The rail‑head slide moves along the horizontal guideways on the cross rail. The ram moves in the vertical slide guideways.

The machine design with the exchangeable heads enables to adapt the machine for as many specified technologic requirements as possible. The exchange of milling heads and of turning tool holders allows to select the optimum type of the milling head for the particular operation with the possibility to use more efficient cutting conditions and at the same time, it enables to enlarge the machine working area.

There is a turning table located in the working area between the columns.

Depending on their equipment, double-column machine SKD permits:

In the turning mode:

- turning the front, cylindrical, conical and general rotation inner and outer surfaces

- turning the inner and outer threads on the cylindrical and conical surfaces, with a constant and variable lead

- frontal and peripheral grinding of frontal and cylindrical, inner and outer surfaces (machines equipped with a grinding attachment)

In the milling mode:

- milling the surfaces and co-axial slots with the head feed (axis X or Z) or with the rotation feed of the table (axis C)

- milling the eccentric slots and general forms with the interpolation of axes X, Z and C

- drilling and boring the openings in the axis and outside the axis of the table with the usage of a precise positioning

- thread cutting in the axis and outside the axis of the table

- milling, boring and cutting the threads under various angles towards the axis of the table (machines equipped with angular milling head)

Material such as cast iron, cast steel, alloy steel and fabricated steel can be machined.