MCV 1680

Vertical machining centre MCV 1680

The MCV 1680 vertical machining centre is a highly productive machine for the complex chip machining. Work table with clamping area of 1800 x 780mm and maximum work load 2500kg moves in the longitudinal direction (X-axis) along the guide ways on the cross saddle. The cross saddle moves along the guide ways on the base in cross direction (Y-axis). The spindle head moves in vertical direction (Z-axis) along the guide ways on the column. All the guide ways are formed by linear guide ways with rolling elements. Their dimensions and location allow high load of the table, saddle and headstock while the high accuracy and quality of workpieces are kept even during interrupted cut. This constructional solution also ensures long service life of the machine. The readout in X, Y and Z axes are performed directly by the incremental linear measuring units. The machine functions are controlled by the CNC control system (HEIDENHAIN, SIEMENS or FANUC) which also enables the machining of the spatially complicated shapes when the tool follows the path resulting from the 3D CAD program output.

The machine in standard execution is equipped with digital drives, linear opto-electric absolute rulers, central lubrication system, ATC with feeding hand, automatic tool holder blowing, cooling unit with tool cooling system, rinsing of telescopic covers and electronic thermal dilatation compensation.

The machine can be equipped with remote diagnostics, which helps with communication with customer in diagnosing and restoring most failures of the machine.

We offer a wide range of special accessories to the MCV 1680, of course.

Machine Main Assemblies

- base

- column

- spindle head

- spindle unit

- planetary gearbox with the circulation-system lubrication

- spindle orientation unit

- tool clamping/unclamping mechanism

- coolant or air supply through spindle axis

- cross saddle

- work table

- axis drive units

- power tracks

- telescopic covers

- roller blind-type cover

- trip dog system with microswitches

- direct measuring system

- electronic thermal compensation of position in axes

- automatic tool changer

- work zone enclosure

- tool outer cooling and telescopic covers wash-out system

- steelbelt chip conveyor and two rake-type chip conveyors

- central lubrication system unit

- pneumatic unit

- air lubrication unit

- hydraulic power unit

- electrical equipment including the foot-operated switch for tool in spindle clamping/unclamping

- flash beacon signalling the end of work cycle

- control system

- control panels

MC1040V

MCG 1000

MCG 820

MCG 810

MCH 1000 FIVE AXIS

MCH 1000

MCH 800 Five Axis

MCH 800

MCH 630

MCV 1000 5 AX

MCU 1100V(T) – 5X

MCU 700V(T) – 5x

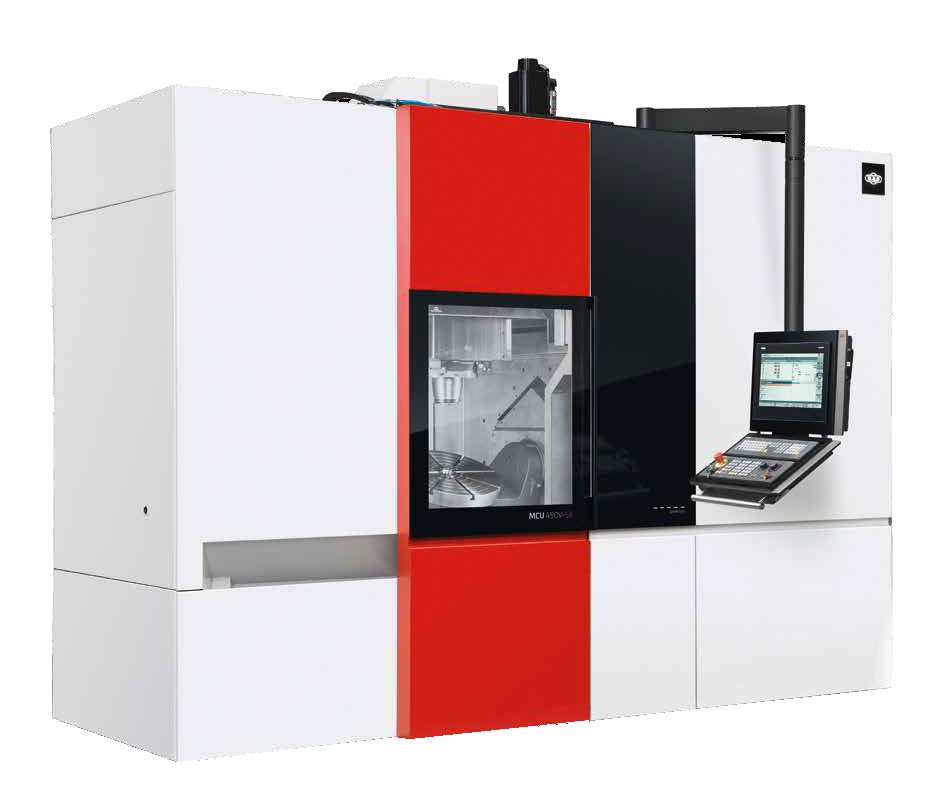

MCU 450V(T) – 5x

MCV 1016 Quick

MCV 1270 Rapid / Sprint / Speed / Power

MCV 800 Quick

MCV 754 Quick

MCV1000 Rapid / Sprint / Speed / Power

MCV 750

MCG 3022

MCG 2318

MCV 2080

MCV 1680

MCV 1260