CKW

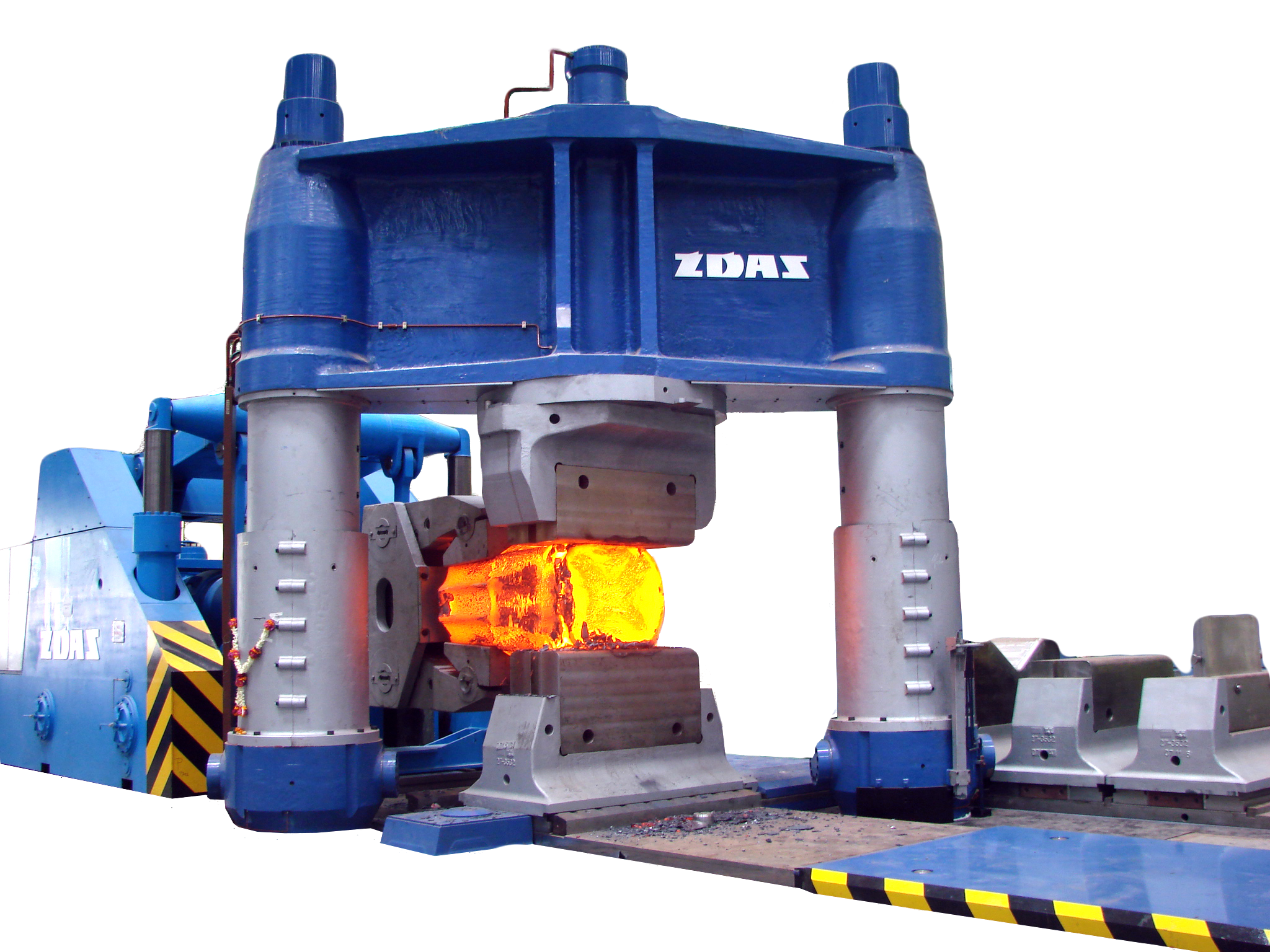

The hydraulic forging press CKW

The hydraulic forging press CKW1600 is of vertical, two-column, pull-down design with movable frame. The press is provided with traversing table, lower tool magazine, lower tool shifting mechanism and upper tool clamping mechanism.

The movable frame consists of the upper and lower cross beams and two columns interanchored using two anchors. The columns are of squared cross section and in the working space they are protected with shields against thermal radiation from the hot forging being forged. The anchors pass through the cross beam hubs and central column bores. The anchors are prestressed using hydraulic nuts.

The middle cross head is a press supporting member. The cross head is fastened on two foundation beams that are mounted in special foundation bearings run in polymer concrete.

The movable frame columns are guided along flat guides mounted in bodies that are screwed to the upper and lower parts of the middle cross head. Considerable distance between the upper guides and the lower ones guarantees low responses in the guides in case of press eccentric load. Increased operating clearances due to worn guide bronze plates are eliminated by inserting a sheet of requested thickness under the plate. Among others, the oil circulation lubrication system removing impurities from the guide areas prolongs service life of the guide bronze plates.

Press working force is generated by one press cylinder built in the middle cross head. The press plunger fastened to the lower cross beam of the movable frame is mounted on the spherical lens and can move laterally.

Reverse motion of the movable frame is performed by four return cylinders of piston design. The cylinders are fastened on hubs of the middle cross head, the piston rods on hubs of the lower cross beam columns. Both cylinders and piston rods are fastened using pins with spherical bearings.

The press is equipped with the longitudinal feed table, lower tool magazine and lower tool shifting mechanism, which fact makes it universal.