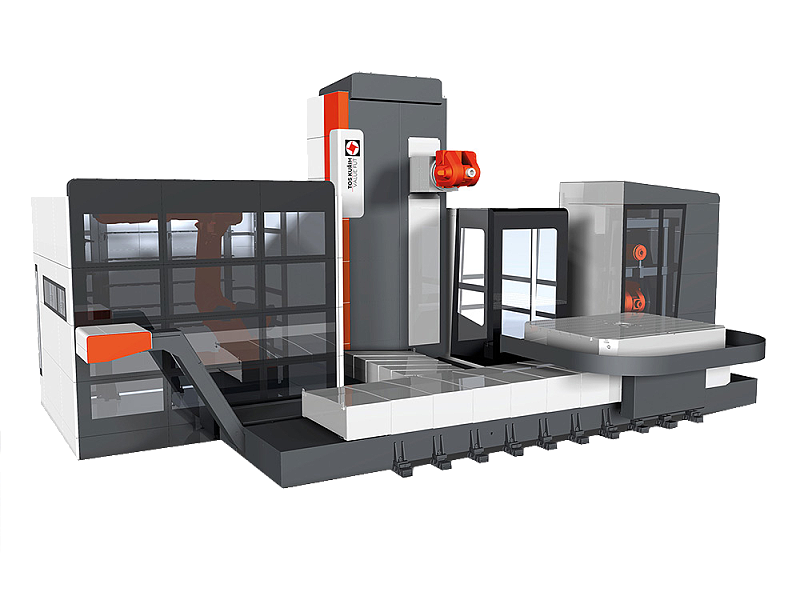

MMC 1500

GANTRY MACHINING CENTER with SINGLE TABLE MMC 1500

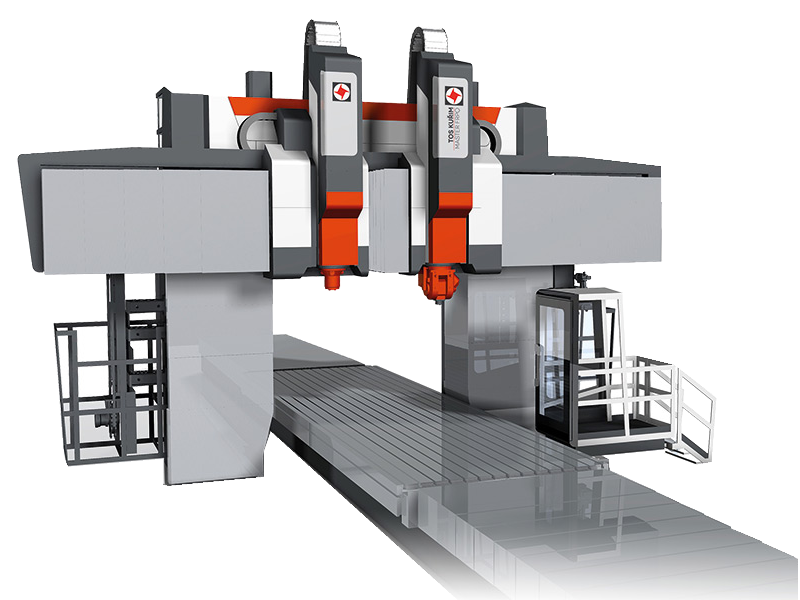

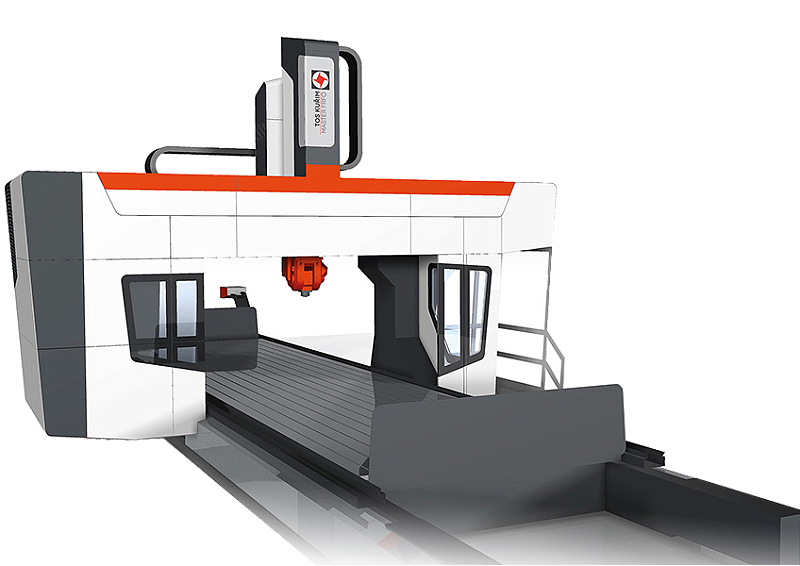

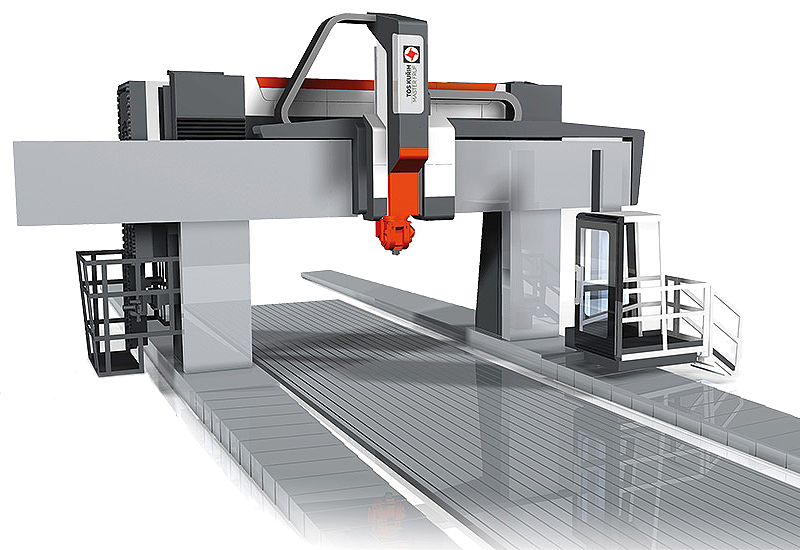

MMC 1500 – GANTRY MACHINING CENTER – is designed for precise and fast machining of general shaped areas like drilling, boring, cutting threads, reaming and milling large and complicated shaped workpieces. This machine have two optional Table variants – single table and dual table „DT” and few Spindle variants: POWER PLUS, POWER, SPRINT, SPEED. MMC is machine with high accuracy and dynamics in axes X, Y, Z (rapid traverse up to 45,000 mm/min and acceleration 5 m/s-2). The working space is 1 500 × 1 000, or in the case of the “DT“ (Dual Table) variant the work table is divided into two separate tables 720 × 1 000. Both working spaces are fully covered and separated. Optional control system – HEIDENHAIN or SIEMENS.

CHARACTERISTIC MACHINE DESIGN FEATURES

- moveable machine parts (table, cross beam, ram) are placed on roller linear guideways

- spindle mounted on accurate bearings with oblique contact

- digital AC drives driving spindle and axis

- measurement by means of linear optic sensors

- centric tool clamping

- control system TNC 640 HEIDENHAIN (SINUMERIK 840D)

MACHINE WORKING AMBIENT

The machine is designed to work in a normal workshop ambient, without influence of aggressive fumes and dust particles. The temperature should be kept in a range from +5° to 40°C, average temperature must not exceed 35°C by max. air humidity of 70%. The machine accuracy is guaranteed at working environment temperature 20 +/-2°C.

In case of machining non-standard materials (e.g. graphite, ceramics, wood, non-ferrous metals) the KOVOSVIT MAS, a.s. reserves right to discuss the way of chips removing from working space (vapor exhausting, cooling liquid filtration, floating chips separation and others technical and technological conditions as well).

The Machine conforms to CE.