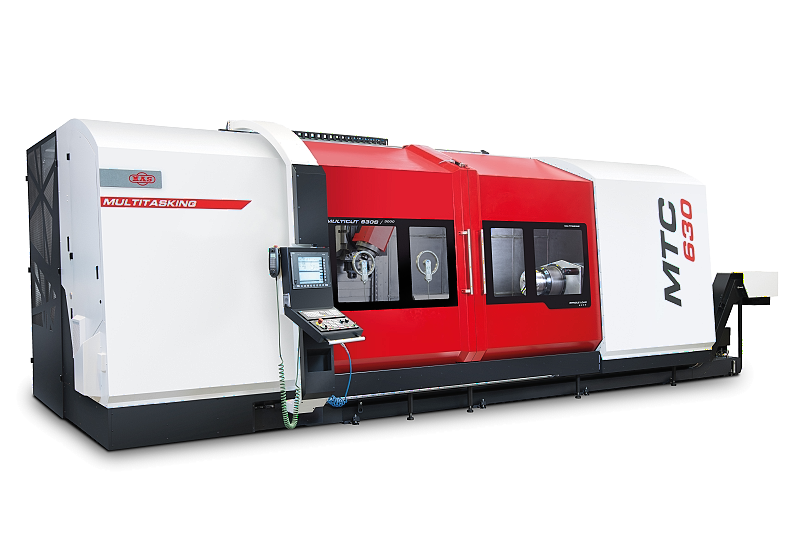

MULTICUT 500i

Multi-tasking turning-milling center MULTICUT 500i

MULTICUT 500i is powerful multi-operational turning–milling center susceptible to combine turning, milling and boring in a single machine within one clamping so maximal increasing of productivity of wokrpiece machining can be reached.

Suitable combination of synchronized movements of work and tool spindle satisfies all technological requirements of turning, threading recessing, drilling, boring, milling, cam milling, gear generating, grinding and measuring incl. possibility to machine slim shafts by means of supporting of a steady rest.

The machines Multicut 500i are produced in the 5-axis execution, which bears also possibility of machining out of axis and 5-axis milling. Mechanical C-axis is solid as additional plug-in axis driven by independent synchronous drive through harmonic gear-box.

The multi-operational turning–milling centers are equipped with high density chain tool magazine for fixed and driven tools with taper HSK A63 or CAPTO C6. All linear guideways are rolling and preloaded. Design of the machine is drawn with maximal respect to good ergonometric characteristics of the machine. The control panel is placed on moveable arms which enables suitable access to the working space, in front and also in the back of the machine – e.g. for comfortable re-supply of new tools into the tool magazine.

Signalling of a state of the machine (beacon) has been placed in the highest post of the machine so the operator has always ideal view about actual machine state. Except the cool liquid tank all elements, which need regular controls and check up of the media, are located in the aggregate unit in the left part of the machine – that allows a simple maintenance of the machine. Big working space windows (from safety glass) provide ideal overview about cutting and adjusting process.

Excellent combination of performance and accuracy is guaranteed with experience and design concept of respective machine groups.

Machine working ambient

The multi-operational turning–milling center is designed to work in a normal workshop ambient, without influence of aggressive fumes and dust particles. The temperature should be kept in a range from +15° to +35°C, average temperature must not exceed 35°C by max. air humidity of 80%, absolute air humidity 15g/m3. Machine tool accuracy according to “Accuracy test report” could be reached when ambient temperature 20 ±2°C. The machine satisfies condition of maximal acoustic supply level 99dB (A) and level of noise by operator 80dB (A). Machine construction corresponds with valid safety instructions.

The Machine conforms to “CE”

Machine version:

- S – version with the subspindle

- T – version with the tailstock