KL285

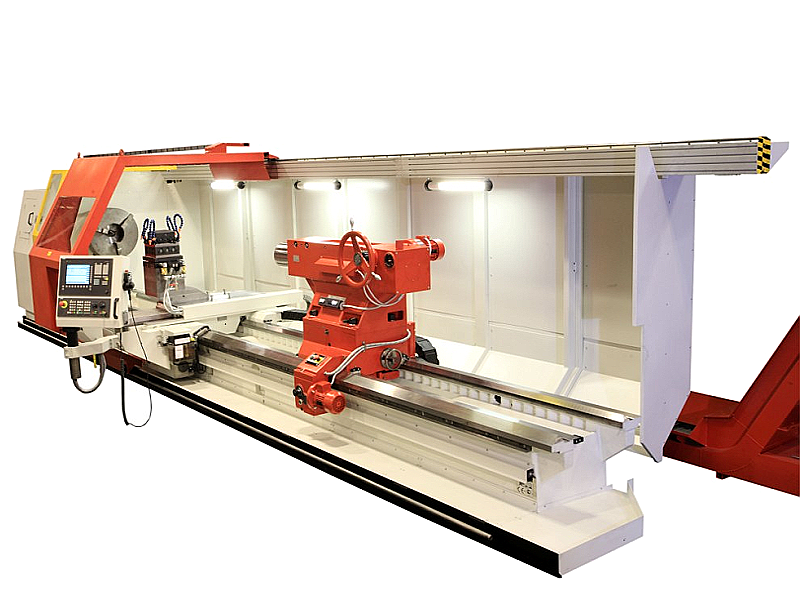

CNC LATHE with driven tools KL285

KL285 (MC)(Y)(SMC)(SY) Super precision is high–performance machine tool with tailstock, driven tools, Y axis and temperature stabilization.

It is suitable for universal and economical machining of flanges, shafts and bar material. A modular system and wide range of special accessories meet requests for turning with one support, same as requests for multi-axis turning. We will appreciate the use of rotary tools during the drilling and milling, especially outside the turning axis by the use of Y axis.

An excellent combination of power and accuracy is ensured by experience and design solution of individual mechanical groups. Synchronous integrated spindle motors provide the high dynamics of spindle function and a powerful rotary axis C. The rolling guide ways in all axes and at tailstock enable higher dynamics of speed. An excellent rigidity and stability of axes movements predestine these machines for production of very accurate work pieces of small batches up to specialized mass production. Transport of machine is either by crane or by means of a forklift.

Standard accessories

- high precious turret (final machining after the assembling of the complete turret)

- axial turret with driven tools (DIN5480) programmable tailstock

- programmable tail stock

- direct measuring of the axis X1, Y1 and Z1

- pressure adjustment and movement of jaws on the control panel

- through-hole clamping cylinder

- spindle locking

- chip conveyor

- manual rinsing of working space

- manual airblast

- machine state signalling (beacon)

- standard painting MAS

- accompanying documentation (note – manual from control system on CD only in English language)

- ethernet, flash memory

- central lubrication

- air adjustment (air supply to the machine necessary)

- control system containing work shop programming (Shop Turn, Manual Guide, Smart Turn)

- temperature compensation – includes the cooling of the ball screw nuts, flanges for the motors and underlay under the spindle unit

MACHINE WORKING AMBIENT

The machine is designed to work in a normal workshop ambient, without influence of aggressive fumes and dust particles. The temperature should be kept in a range from +15°C to +35°C, average temperature must not exceed 35°C by max. air humidity of 80%, absolute air humidity 15g/m3. Machine tool accuracy according to “Accuracy test report” could be reached when ambient temperature 20 ±3°C.

Does this model not meet your needs? We also have bigger option. More information to be found in our catalogue. The manufacturer reserves the right to change the product parameters and design without prior notice.

KL285

KL435

SE520 SL

SR1, SR2, SR3, SR4, SR5

MANURHIN K’MX 1032

MANURHIN K’MX 916 CLEVER

MANURHIN K´MX816 CLEVER

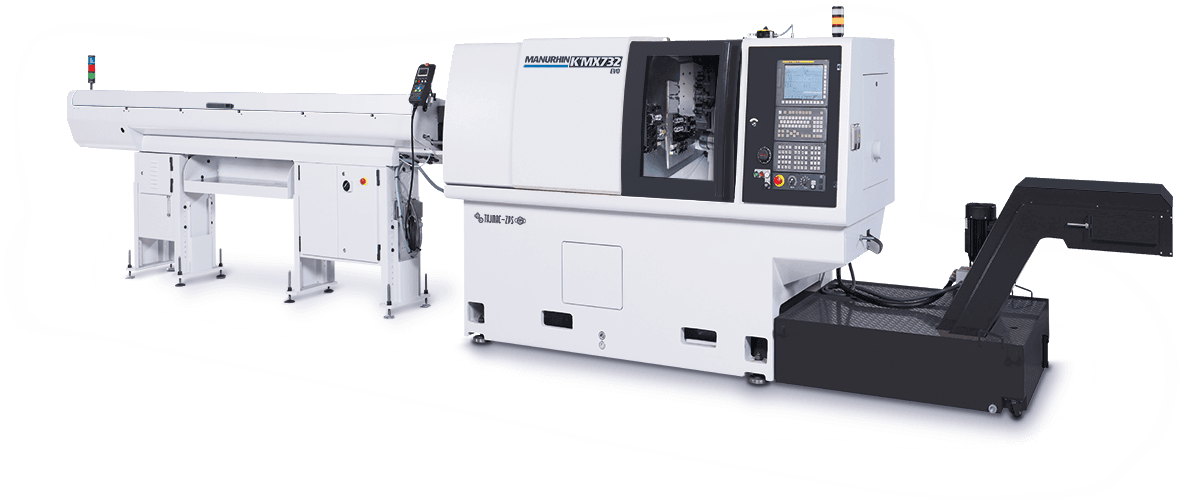

MANURHIN K´MX732EVO

MANURHIN K´MX632DUO

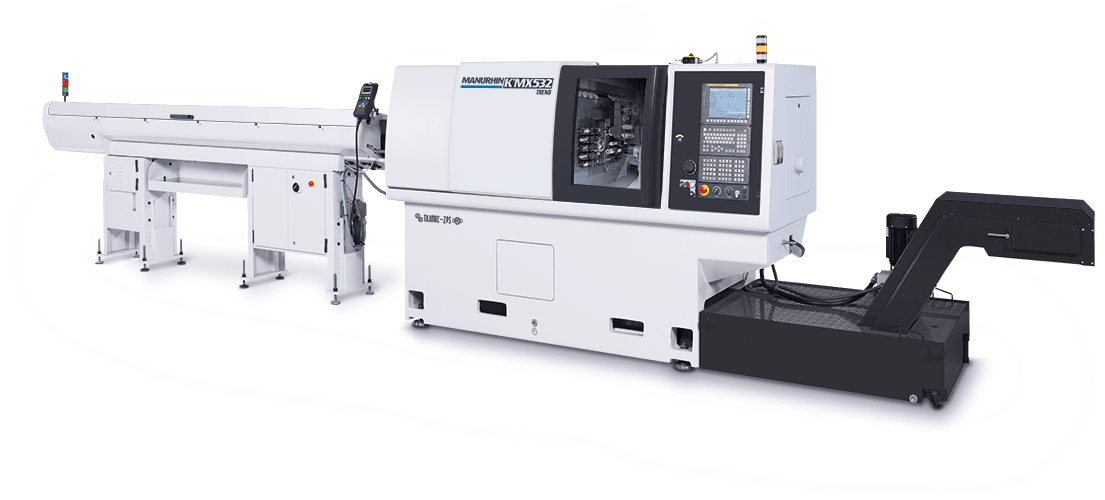

MANURHIN K´MX532 TREND

MANURHIN K´MX432

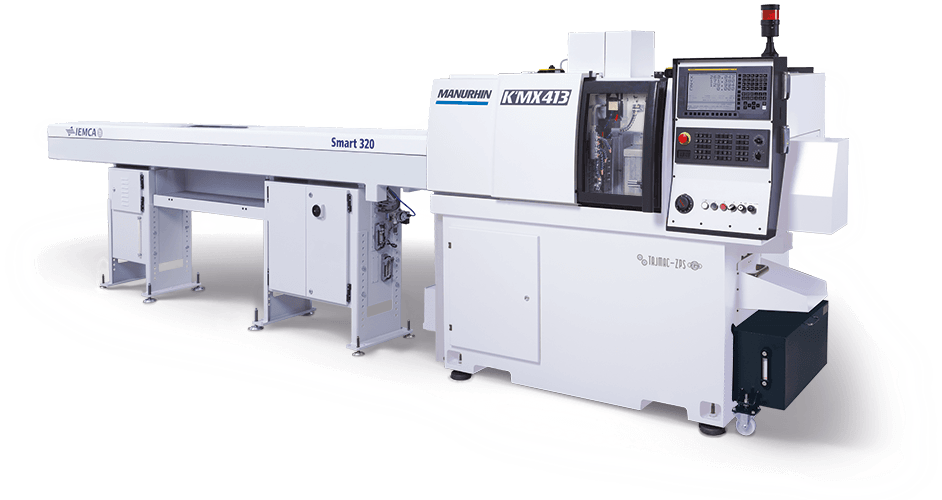

MANURHIN K´MX413

MORI-SAY TMZ867 CNC

MORI-SAY TMZ842 CNC

MORI-SAY TMZ642 CNC

MORI-SAY 832AC / 842AC

MORI-SAY 657AC, 667AC

MORI-SAY 632AC / 642AC

MORI-SAY 620AC

SPH 50 / D / DS

MASTURN

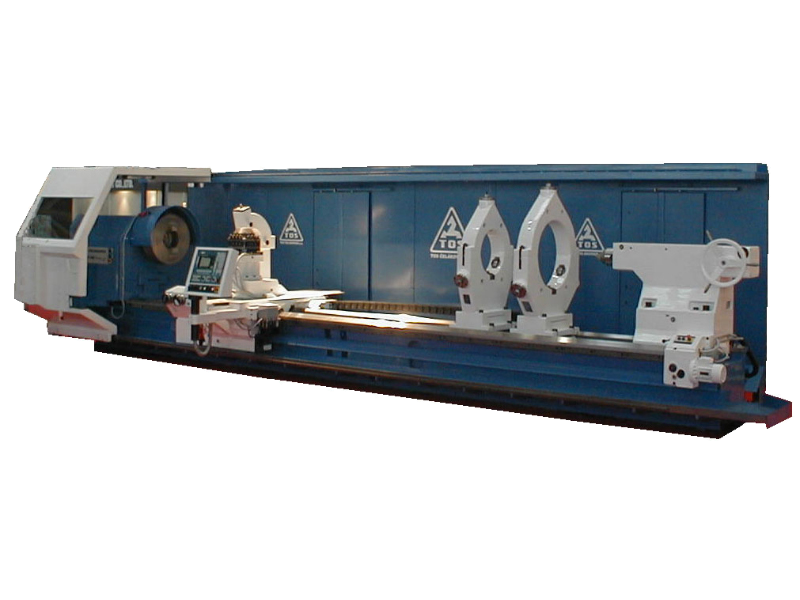

SUA 150 Numeric

SUA 125 Numeric

SUA 100 Numeric

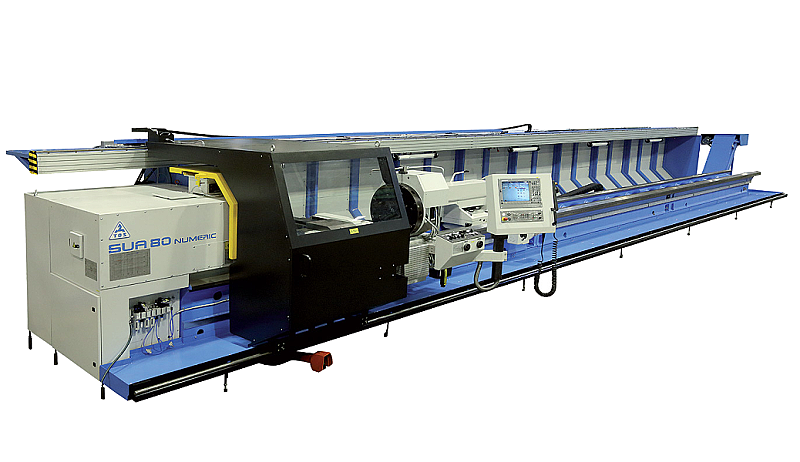

SUA 80 Numeric

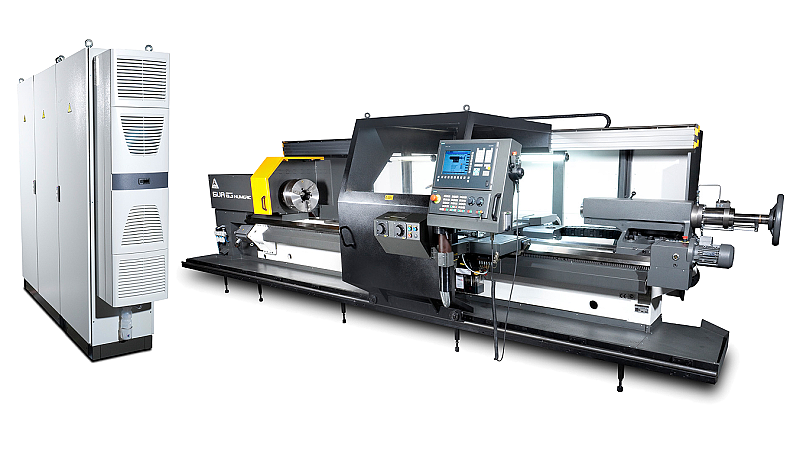

SUA63 Numeric

SBX 500 CNC

SBE300 CNC

SBL 700 CNC

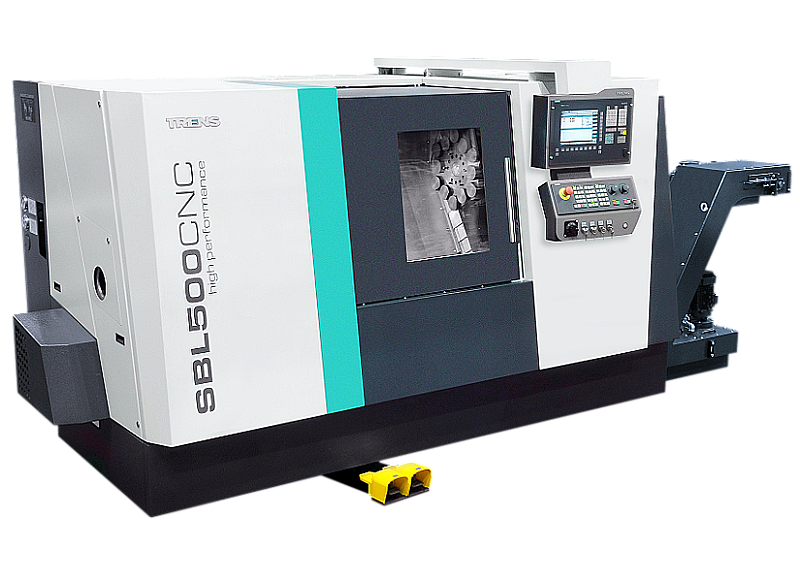

SBL 500 CNC

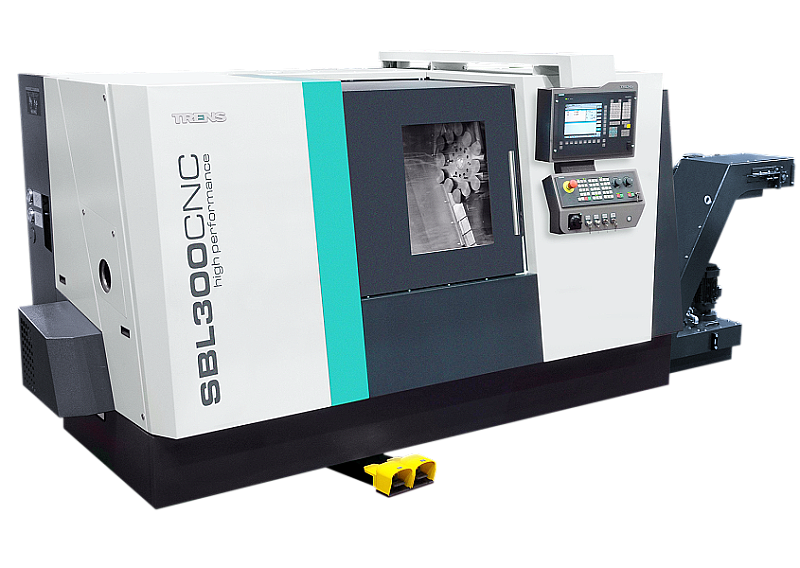

SBL 300 CNC

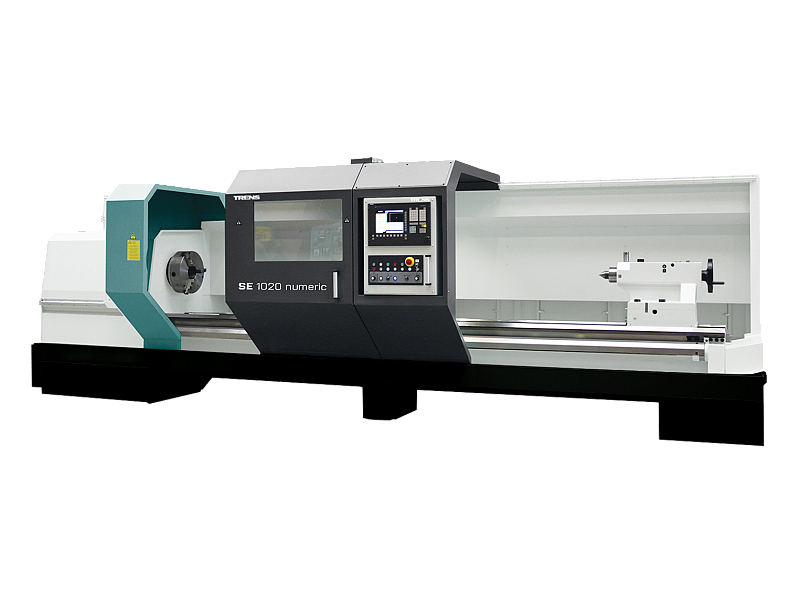

SE 1020 NUMERIC

SE 820 NUMERIC

SE 520 NUMERIC

SE 320 NUMERIC

https://www.youtube.com/watch?time_continue=1&v=6Nt9tUAWeKQ&feature=emb_logo